As an innovative enterprise specializing in heat pump control technology, we have always taken R&D as our core driver, establishing a comprehensive R&D system from core algorithm development to full-scenario application testing and validation. We deliver efficient, intelligent, and reliable heat pump control solutions to global customers. Our R&D team comprises over 30 engineers with both theoretical expertise and hands-on engineering experience, specializing in heat pump system control logic, energy efficiency algorithms, and IoT integration.

Furthermore, we have invested in an industry-leading R&D and testing center, equipped with world-class equipment. It covers multi-dimensional testing—including environmental simulation, performance evaluation, and reliability validation—tailored to heat pump operating conditions, providing solid technical support for product stability.

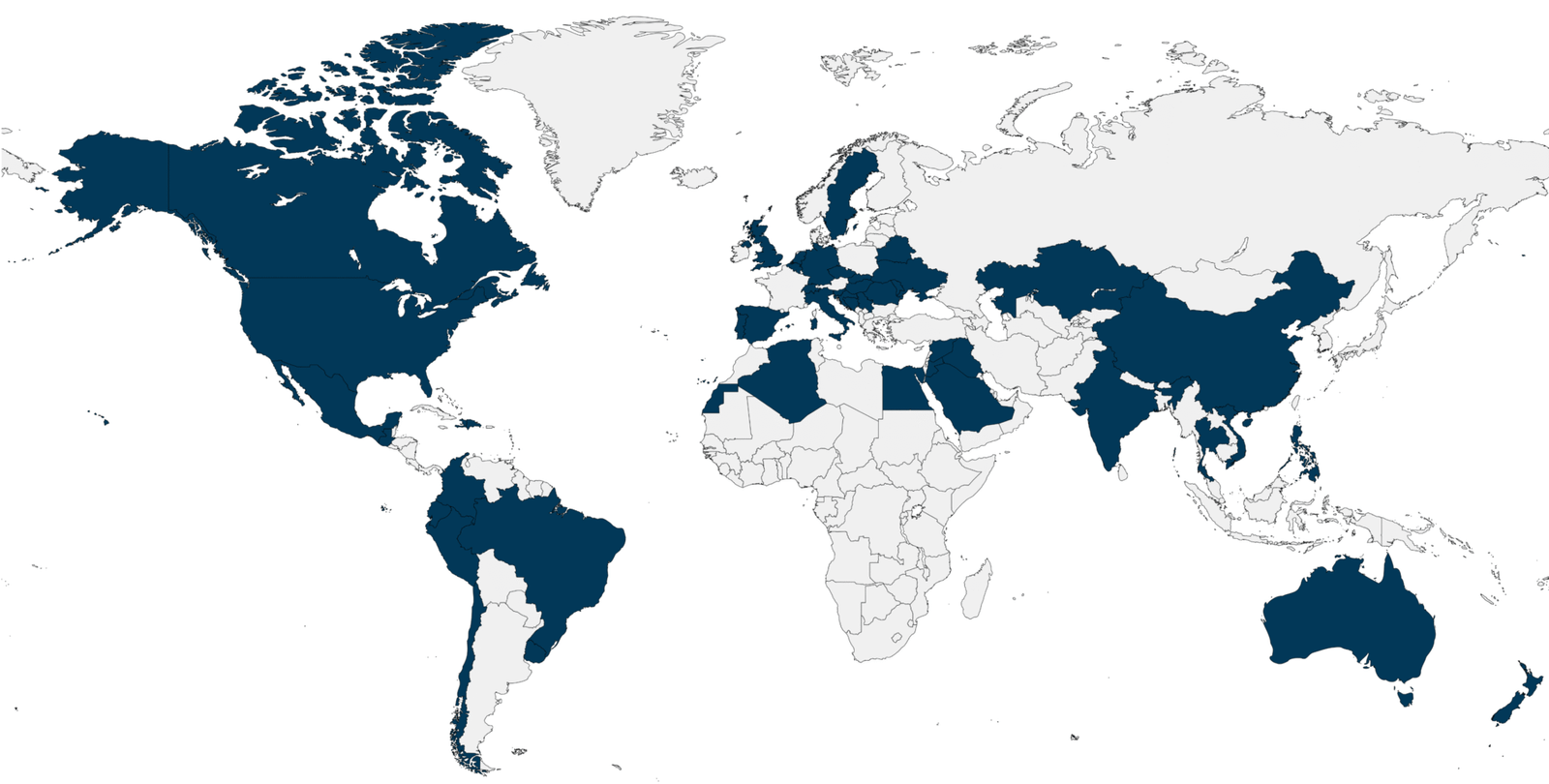

Backed by a modern production base, we currently achieve an annual production capacity of 300,000 heat pump controllers, covering multiple product series such as commercial swimming pool, inverter heating, and triple-generation (cooling, heating & hot water) systems.

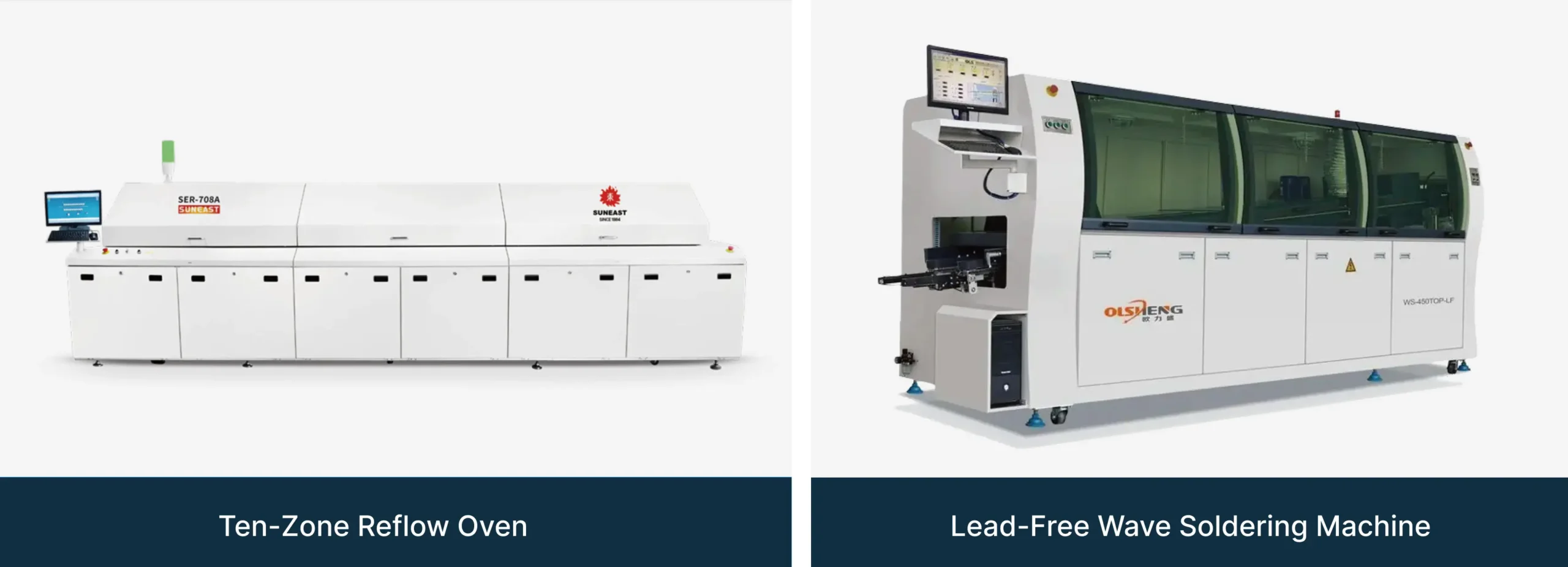

The production line is equipped with imported automatic placement machines, high-precision welding equipment, and AI visual inspection systems, enabling full-process automated control from SMT placement to complete machine aging testing. It can flexibly meet the order delivery requirement of over 10,000 units per month, satisfying large-scale procurement needs of both domestic and international customers.

Mature Full Inverter Technology

With over 20 years of R&D in inverter control technology, Ausolan has developed mature full inverter control solutions, which have been applied to various types of heat pump products. Our inverter control algorithms enhance energy efficiency by 20%-60%, delivering significant energy savings for customers.

Safe And Stable Use Of Refrigerants

Our control systems enable safe and stable refrigerant operation: 50% of heat pump units integrated with our controllers utilize R32 refrigerant. We also support R290 refrigerant applications with built-in leakage detection and explosion prevention controls, ensuring compliance with safety standards.

Smart Control Technology

Ausolan boasts advanced smart control technologies, including IoT-enabled remote monitoring, real-time data analytics, and intelligent fault diagnosis. Our controllers support seamless connectivity for remote parameter adjustment and performance tracking, enhancing operational efficiency for end-users.

Low-temperature Operation

Our low-temperature adaptive control algorithms enable heat pumps to operate stably at ambient temperatures as low as -30°C, while maintaining hot water output up to 60°C. This exceptional performance in extreme low-temperature conditions is achieved through precise compressor modulation and adaptive defrosting logic.

Customization

Customer-centric ODM & OEM Services: We offer tailored control solutions, including custom hardware design, software programming, and algorithm optimization, to meet customers’ unique heat pump application requirements.

Excellent quality assurance

Ausolan adheres to stringent quality standards and sustainable design principles, earning trust from global partners. Our commitment to quality is backed by: a skilled engineering team, advanced automated production lines, premium-grade components (e.g., industrial-grade ICs), and rigorous testing processes (from component-level validation to system-level reliability trials).